Isolation voltage of current sensor -6KV isolation - safety protection - [Wickway]

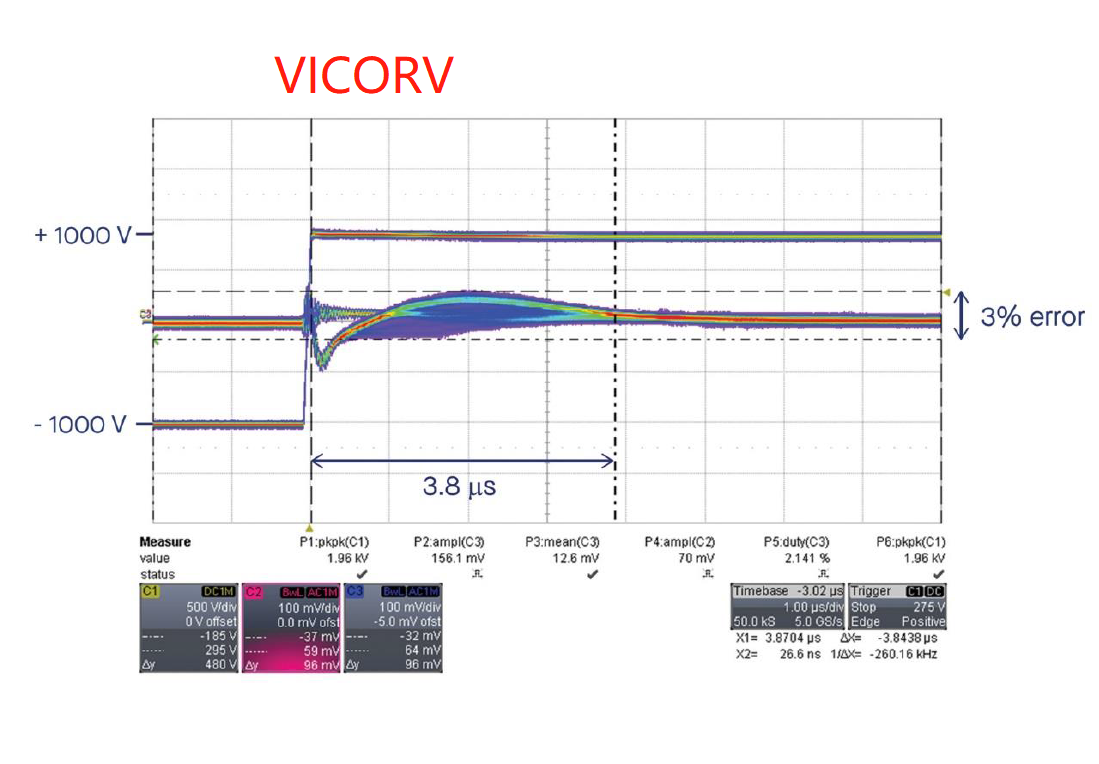

The low interference generated by the application of dV/dt is displayed through the sensor. The generated error is only 3% of the full scale, and the recovery time is 3.8us. The HMSR20-SMS is tested with a pulse voltage of+/-1000V at 20kV/uS: the two available built-in OCDs on the HMSR will also protect the transistors on the inverter from overload and short circuit.Isolation voltage of current sensor58彩票This type of detection and protection is important for various applications, such as HVAC or motor drive applications on DC connections. Most modern variable frequency drives (VFDs) combine motor overload algorithms with OCD functionality on HMSR to make detection easier and prevent overheating of equipment. There are two different OCDs that provide separate monitoring for overload and short circuit events. Of course, isolation requirements may be a problem when choosing current sensors when using integrated circuit packaging. For example, solar power plants are typically used for higher DC voltages, up to 1500V, to increase the DC/AC power ratio. This greatly increases the isolation required for the current converter. The longer internal distance between the primary and secondary sides helps to isolate the primary current from the rest of the IC, ensuring a voltage of 4.95kVRMS (1 minute at 50 Hz AC insulation test voltage).

Thanks to our advanced production and assembly capabilities, the testing quality of all shipped products during the production and assembly period can be better guaranteed. The special HMSR's footprint allows for an 8mm creepage distance and clearance distance at sea level. A higher comparative tracking index (CTI) means a lower minimum creepage distance according to IEC 62109-1 (power safety), requiring distance, and CTI greater than 600 for converters used in photovoltaic power generation systems. The operating voltage of HMSR reaches 1600V, which means it is very suitable for this high-voltage application. Another key requirement of the solar energy industry is that equipment needs to rapidly grow and withstand up to 20kA, providing effective lightning protection. Placing HMSR directly on a string input that is susceptible to lightning strikes, the component will have extremely strong lightning resistance to such powerful current surges. In fact, the design and testing of HMSR have reached this level according to the standard 8/20 American surge test profile.