Layout of current sensors for photovoltaic inverter power supply - Faster response - Professional FAE guidance - [Weikewei]

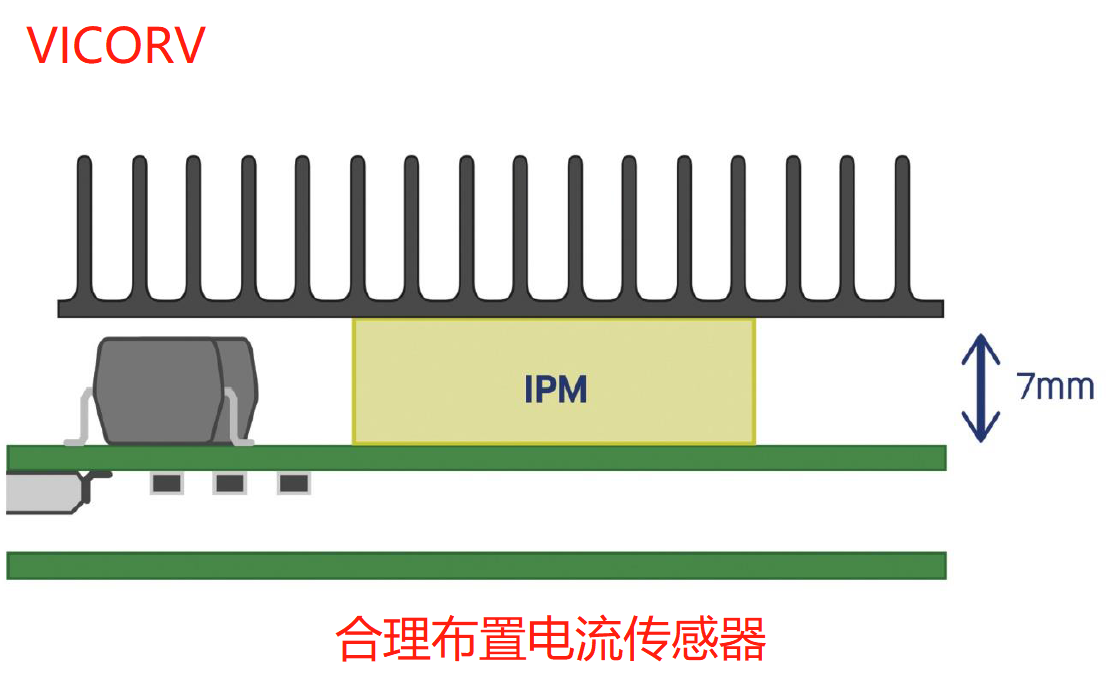

If the current sensor only has high accuracy without fast response time, such accuracy is not enough. To this end, the deployment of fast IGBT,Photovoltaic inverter power supply current sensorLayout is important, and with SiC technology, the possibility of operating at faster switching frequencies has been increased. HMSR has been proven to be ready for high demand technologies with response times below 2uS. In various applications, HMSR sensors can be directly mounted on printed circuit boards as SO16 mount devices, reducing manufacturing costs and providing much-needed space savings for restricted environments. Standing only 6 millimeters tall, HMSR provides significant space savings in applications, making it an ideal choice for placement under heat sinks instead of smart power supplies as an IPM (see figure below).

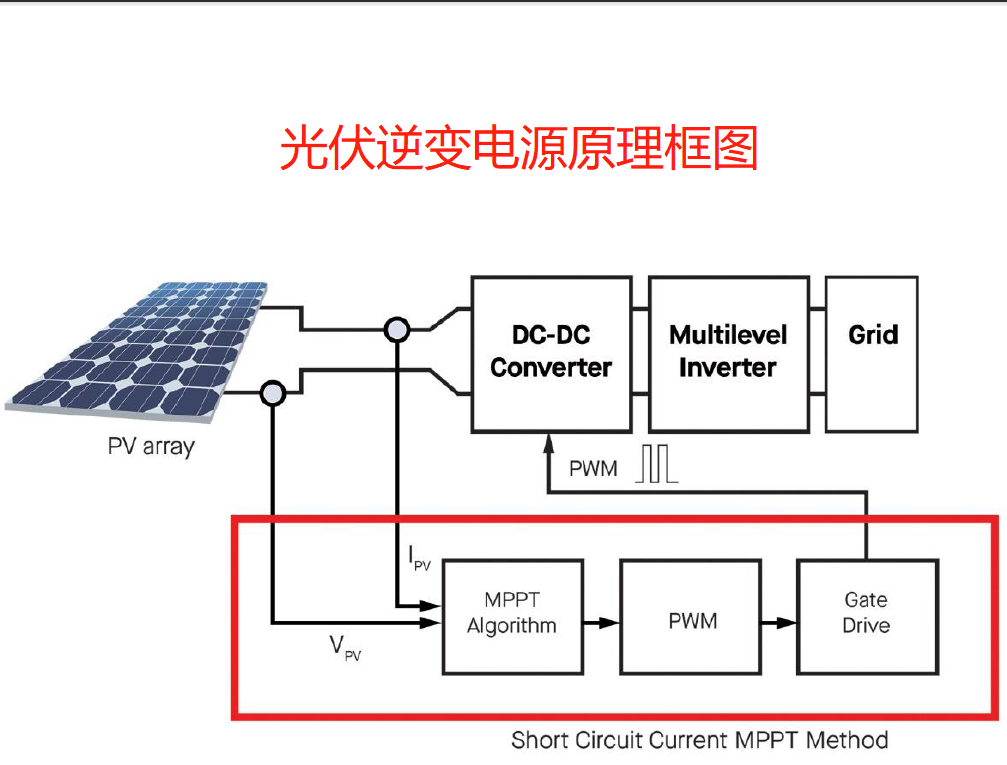

58彩票Another HMSR will be measured in current solar applications. Especially the Maximum Power Point Tracker (MPPT), which is an important conversion of solar energy, is a collection of components that maximizes the utilization of photovoltaic (PV) panels. It is based on the system's temperature, sunlight, and total resistance. Analyze the system output after injecting small disturbances into the permanent control system using perturbation and observation methods. Then MPPT analyzes the generated power (by sensing voltage and current) and deducts the parameters to be changed to achieve the maximum power point. MPPT then changes the pulse width modulation (PWM) to adapt to the DC/DC converter.

58彩票The higher the accuracy, the lower the noise, and the better the performance of MPPT. Using advanced ASIC current sensors, HMSR provides a highly accurate low-noise signal, enabling the system to operate at its optimal level. More importantly, current monitoring enables the comparison of multiple components and the detection of issues such as wiring errors, dirt on panels, and the impact of growth. Here, the high precision of HMSR will enable string comparison. In addition, the DC/DC converter used in MPPT employs high-frequency regulation (approximately 80kHz), resulting in high dV/dt that is harmful to electronic components. Thanks to its sturdy design, HMSR provides tremendous resistance in such noisy environments. This immunity can be easily checked by applying dV/dt through sensors and observing the output response.