Switching power supply uses Hall current sensor - Hall current sensor - Weikewei

Switching Mode Power SupplyPower factor calibration in(The PFC power circuit and rectifier circuit must both detect the current data signal on the high voltage side to the control board at the low voltage end,Therefore, protective measures should be adoptedHall Current Sensor . There are various methods for implementing protective current detection, such as current and voltage transformers(CT)、 Protective amplifier and Hall effect current sensor. Among them, Hall current sensors have become a more ideal choice due to their simplicity, practicality, accuracy, small size, and ability to detect direct current.

Current and voltage transformers are used to sample current based on the basic principles of transformersCT can detect the enable current of MOSFET or IGBT. The rapid response time of CT makes it particularly suitable for high-value current manipulation and overcurrent protection manipulation. However, according to the basic principle of transformer coupling, CT cannot sense direct current or very low frequency current, which results in its inability to immediately detect direct current or alternating current, or damages the accuracy of accurate measurement due to the indirect method of only detecting the enable current (without turning off the current). In addition, because CT requires the use of magnetic cores, it is difficult to make the volume small, and CT with a large volume will expand the power supply main switch circuit, causing higher working voltage peaks and noise effects.

The Hall effect current sensor is a more accurate and smaller option, which can In operation under DC standards, it can accurately measure with excellent linearity and precision, including enabling and disablingTotal AC current. In addition, the volume of the Hall effect current sensor can ensure the packaging of SOIC-8, with the same size as an integrated IC, making the reasonable layout of the PCB easier and conducive to achieving higher power.

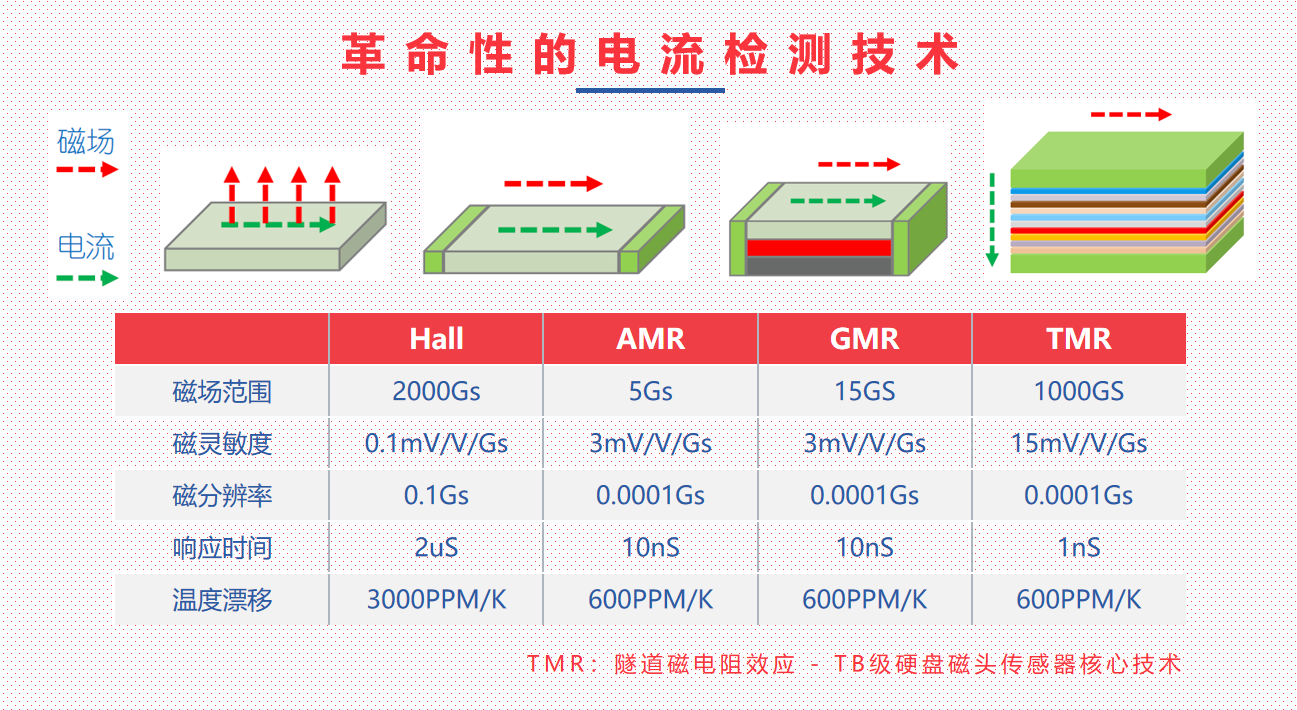

surfaceA pair of Hall effect current sensors and current voltage transformers were developedcompare.

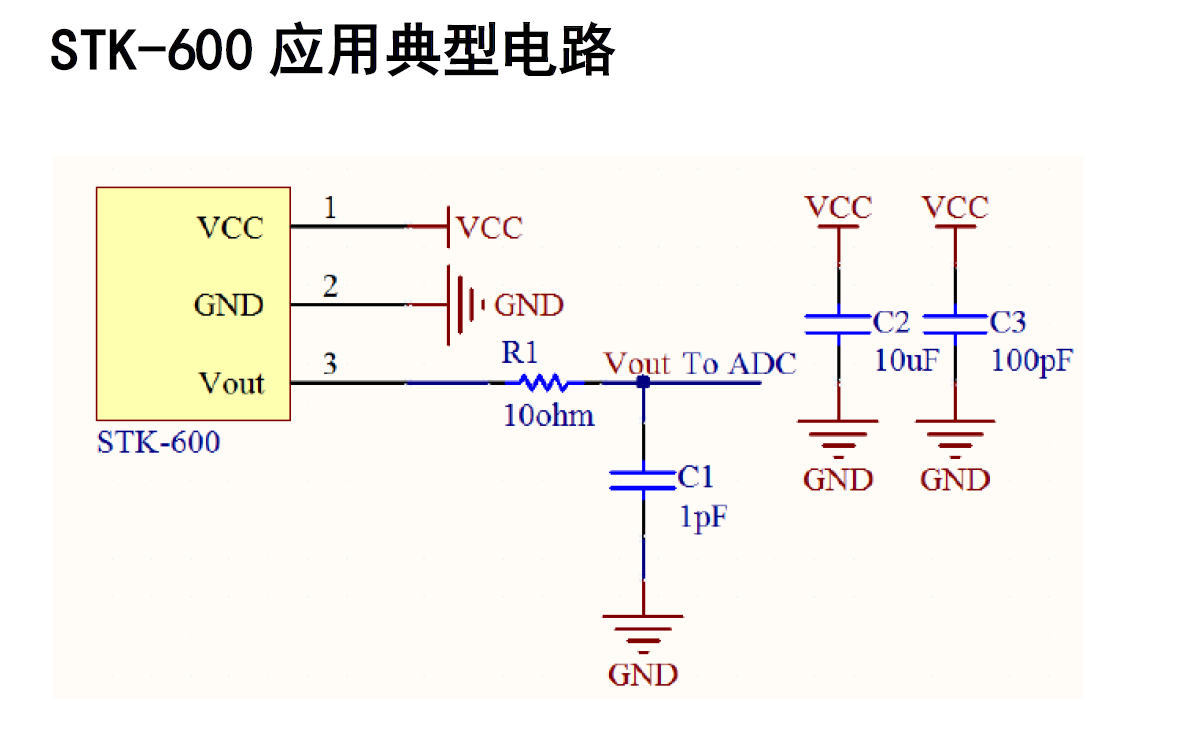

Applying Hall current sensors to switch mode power supplies or network serversWhen using PSU, it is necessary to evaluate the detection range of current, the ability to withstand continuous current, the response time (/network bandwidth), and the protection level of working voltage. In some cases, telecom network switching power supplies or server power supplies may also need to report the current operating output power to the upper computer software. In this case, high-precision Hall element current sensors (such as Weikewei's STK-600AM) can assist the system software in achieving a current detection accuracy of ≥ 1%.

chart1 shows the typical application of Hall effect current sensors in power supply circuits under 3.3 V and 5 V power supply system conditions. Compared with the application of a 3.3V switching power supply system, the application of a 5V power supply system can expand the current detection range of Hall elements. withSTK-616YFor example, the sensitivity of Hall elements is50 mV/A: If a 3.3V switching power supply is applied, the current detection range is -33 A~33 A (dual); When using a 5.0V switching power supply, the current detection range can be expanded to -50 A~50A. In addition, in the design scheme, it should be noted that in addition to the current detection category, the continuous current tolerance of the sensor must also be considered. When the current tolerance is insufficient, it can be based onImproving the SensorscatteredHeat to increase.

(a)

(b)

chart1: The common application of Hall effect current sensors:

Select a Hall effect current sensor with a 3.3V switching power supply (a);

Hall effect current sensor using 5V switching power supply (b)

In the applicationHall Current Sensor In the reasonable layout of the circuit board, attention should be paid to the following elements:

Heat dissipation: Expanding the total copper coverage area of the primary side current transmission line as much as possible can enhance the heat dissipation capability of the Hall element current sensor, thereby improving the sensor's ability to withstand larger average currents. In addition, thicker copper pots can also be appliedPCB, Alternatively, placing some heat dissipation through holes on the grid in the middle and middle stages, or placing the Hall element current sensor and PCB wiring inside the air duct, can improve the average current carrying capacity of the Hall element current sensor.

Primary side current electromagnetic field: When arranging reasonably, it is advisable to minimize wiring with high currents that are close to Hall element current sensors.

Protection regulations: Considering the overall breakdown voltage and electrical clearance of the system software, when the Hall element current sensor cannot meet the requirementsWhen the PCB breakdown voltage occurs, it is possible to cut slots on the circuit board to achieve system software level protection regulations.

Summary: In telecommunications network ballasts and network serversIn PSU, CT is more suitable for high-value current manipulation and overcurrent protection, but it has a large volume and low accuracy. The Hall effect current sensor has a small size, high accuracy, simple and convenient application, and is more suitable for detecting communication and AC line currents.