Research on F16 Distribution System - Aviation Contactor - [Wickway]

According to the information obtained by the Wei Kewei editor, the manufacturer of F16, Lockheed Martin, will beResearch on F16 Distribution SystemInnovate and attempt a new electronic static hydraulic flight control and power system. Used for the Joint Strike Fighter (JSF), it is expected to completely change the technology of telegraphy. The Lockheed Martin company's JSF team called it "wired power supply" and developed the system, which was flown on the US Air Force F-16 as part of the Joint Strike Fighter Integrated Subsystem Technology (J/IST) project. The design of electric actuators actually originated from the United States Air Force Research Laboratory.

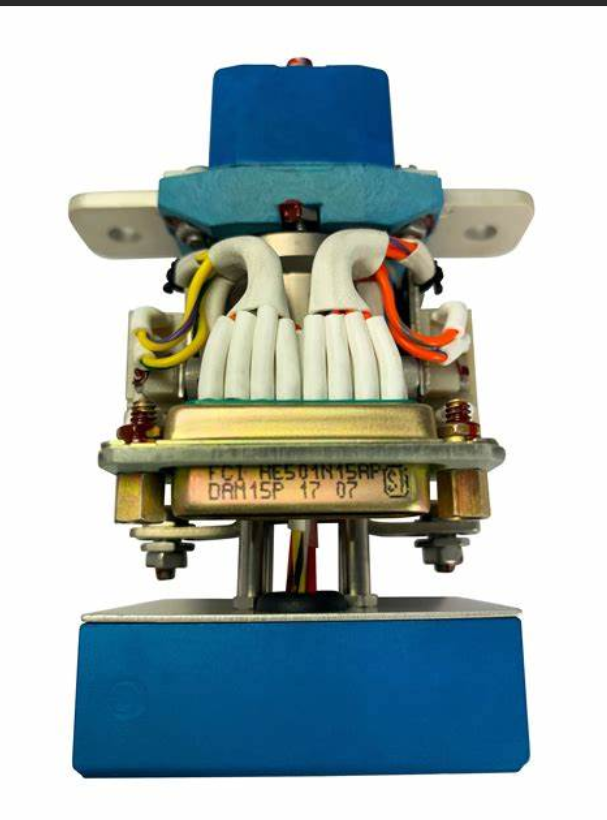

Lockheed Martin believes that the significance of this system in reducing fighter jet risks will be as important as when the F-16 became the first production fighter jet in the United States equipped with fly by wire control in the 1970s. The main telecommunication components,Aviation contactor58彩票Innovation in this area is also an important topic. This is the first generation of the new generation of flight control technology, "said Dennis Eicke, J/IST project manager at Lockheed Martin Aviation." We have achieved success in the development, integration, and testing of (the system)

Lockheed Martin included a wired power supply system in the X-35 Preferred Weapon System Concept (PWSC) design proposal submitted in February for the Engineering and Manufacturing Development (EMD) phase of the JFF project. This information has been shared with Boeing, a competitor of JSFs. Despite offering different flight control and drive systems in its X-32 design (see sidebar), the JFF project office can authorize Lockheed Martin to produce fighter systems, regardless of which team wins the competition.

The new distribution system will achieve good results in reducing weight and cost.

The new flight control subsystem package includes an on-demand electrical system and electric drive for the flight control surface (instead of traditional, large, heavy, and difficult to maintain hydraulic drive). Lockheed Martin insists that government research shows that the new approach can reduce procurement costs by 5%, lifecycle costs by 3%, and total takeoff weight by 6%.

Ike said, "We found that if we use electricity, emergency and secondary power systems will be simpler and cleaner. It makes airplanes smaller and simpler

He added that it can reduce aircraft weight by up to 700 pounds (315 kilograms), but not because the system itself is lighter We subtract weight from the hydraulic system, secondary power system, and thermal management system because we don't generate as much heat.