Current sensor in system integration, [Wickway], reduces volume by 47%

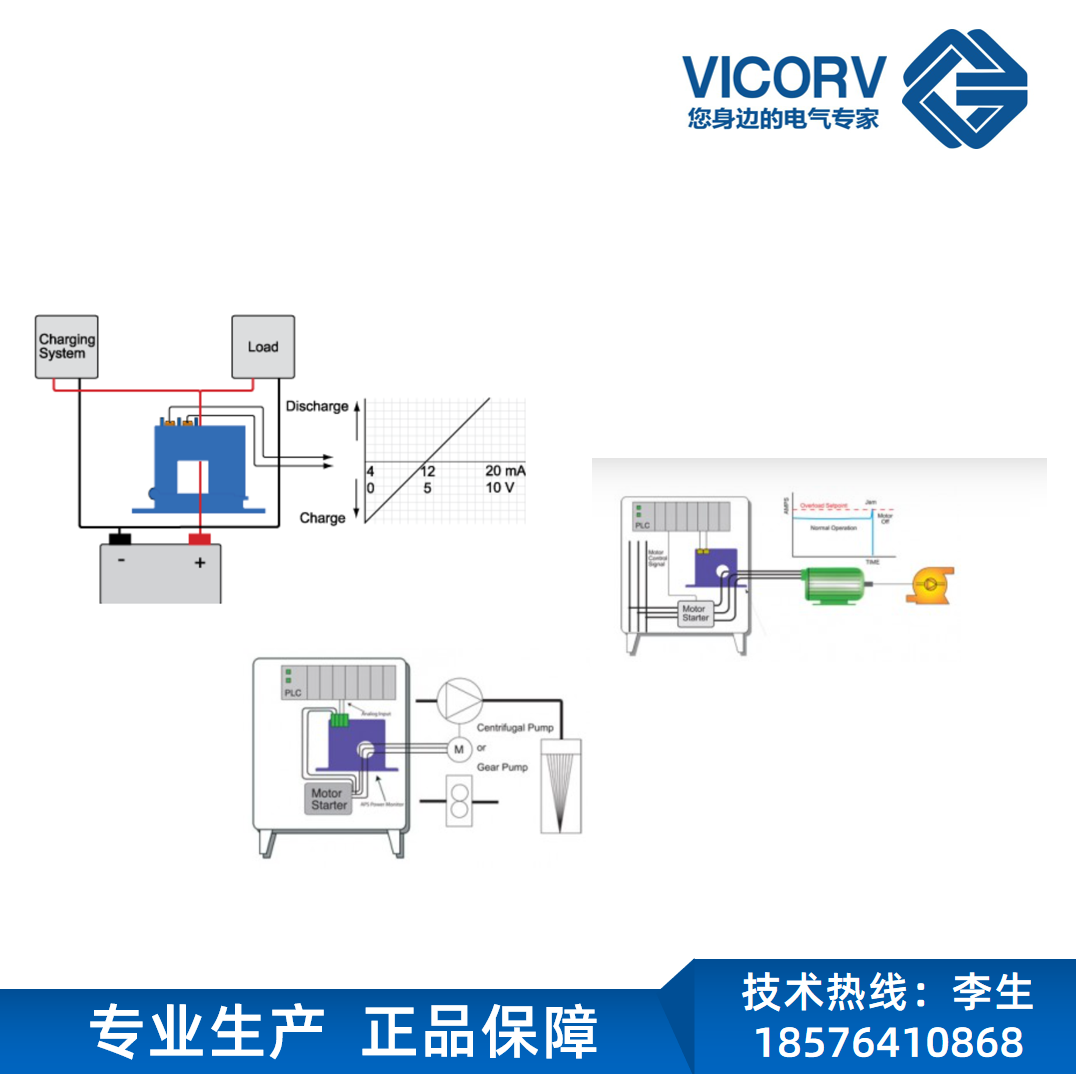

Current sensors are an economically effective method for measuring the work being done during a process and detecting potential issues before they become catastrophic failures. Blockage of the air inlet or loss of pressure head in the pump system can cause the driving motor to consume less current than normal levels. If the discharge outlet is opened, the same situation will occur, which means immediate intervention is needed in the sewage lifting station. Bearing failure can cause the electric motor to consume more current than normal; Before the overload protection in the starter is activated, using a current sensor will notify the operator of the problem. Additionally, if the system designer chooses, a current sensor can be used to shut down the system.

alternating current

Many AC motors are driven by variable speed drives to save energy, and although the output is much cleaner in terms of waveform, none of them are sine waves. The RMS response sensor will generate a signal proportional to the current used, which can be connected to a second driver to match the speed or workload. Accurately monitoring heating loads controlled by phase triggered SCR also requires RMS sensing, but simple current switches or relays will detect whether components have malfunctioned, rather than causing delays solely due to temperature monitoring. When the pump or drive motor operates at a low power factor, the monitoring current may not be sufficient. Monitoring power will generate a signal proportional to the watts (power) being used. NK Technologies' APS sensor is a very compact self-contained device that can perfectly accomplish this task. One phase passes through a hole from left to right, and the other phase passes through from right to left. Both monitored phases are connected to the circuit voltage. Through this unique on-site wiring method, the sensor can continuously measure current and voltage, and generate a 4-20mA loop powered signal that represents true power, not just volt ampere.

Direct current

DC systems are becoming increasingly common, and photovoltaic panels are being used more and more in households and businesses. Compared with current dividers, it has many advantages: there is no need to cut and terminate conductors, the non-contact characteristics of sensors add burden to the system, and the errors caused by temperature changes are greatly reduced. The DC current sensor produced by NK Technologies has a range of 0-5 to 0-2000 amp and provides various outputs to interface with panel instruments, programmable logic controllers, or building energy management systems. Sensors can be used to monitor any DC voltage up to 600 and still carry the UL mark, making your panel design safe and accurate in various applications. Whether the load is using batteries as backup batteries, or it is necessary to know the main power source and current direction, or to monitor and study welding operations, NK Technologies' sensors have the range, accuracy, and reliability you need and the customer's requirements