Current sensor improves power efficiency - Wickway - reduces temperature rise by 47%

58彩票Conversion and power management applications increasingly require current sensors with reliability, durability, and accuracy. The next generation of electronic devices will face significant technological challenges, which will affect power management performance and efficiency. It is necessary to carefully select the current sensors necessary for monitoring the power absorbed by the load and controlling and protecting the power supply, and occasionally choose the most suitable solution sensors for specific applications in Hall effect sensors, transformers, shunt resistors, or AMRs. According to the type of electrical insulation, current sensors can be divided into two categories: isolated sensors and non isolated sensors. Non isolated sensors are suitable for applications with low voltage levels, typically below 50 V AC or 120 V DC. It is necessary to use isolated sensors at higher voltages and powers, or in the case of floating measurements. The first type of isolation sensor can be made using shunt resistors and optical or capacitive insulators. Another solution is to use magnetic current sensors. The first component requires a certain number of external components in addition to parallel resistors, while the second component is a single-chip solution that only requires an integrated magnetic IC.

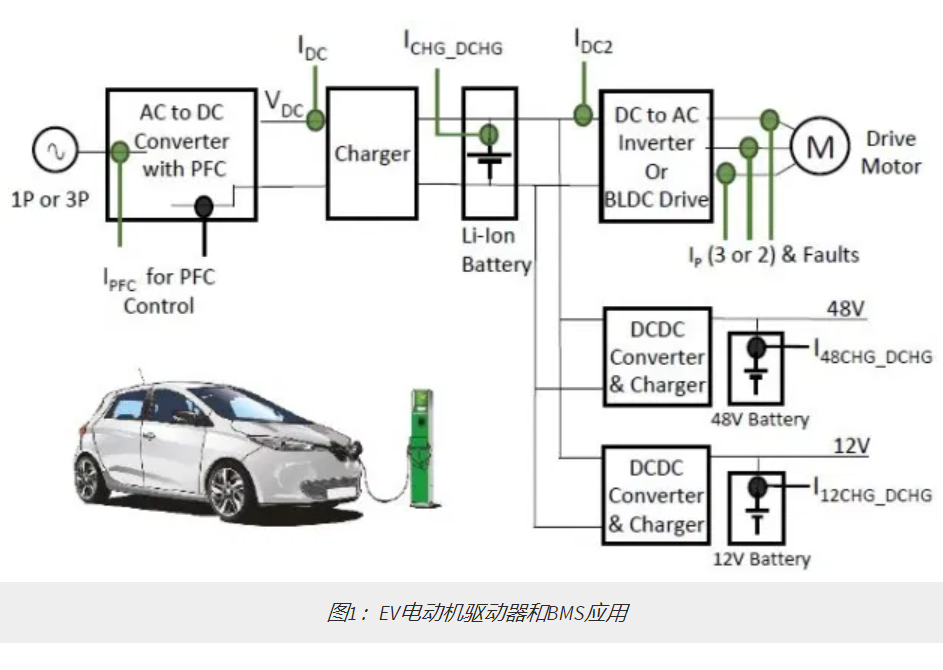

58彩票Magnetic current sensors can be used in any application that requires power conversion, including power supplies for data centers, servers, and telecommunications. The first stage converts single-phase or three-phase AC power into DC voltage, usually including a PFC circuit to achieve higher efficiency. The following stages are represented by one or more DC-DC converters that generate the voltage required by the load (for a single CPU, this voltage is 48V, 12V, and as low as 1V); Motor drivers and inverters. Here, the first stage is an AC-DC converter with PFC, followed by a three-phase DC-AC inverter. Uninterruptible power supply (UPS). The AC-DC converter with PFC is followed by a battery charger and a battery pack, until it reaches a DC-AC inverter. EV electric motor drive and battery management. Figure 1 shows the different stages involved in this application. In this case, as a further output stage, we have two DC-DC converters and a charger to power the 12V and 48V batteries.